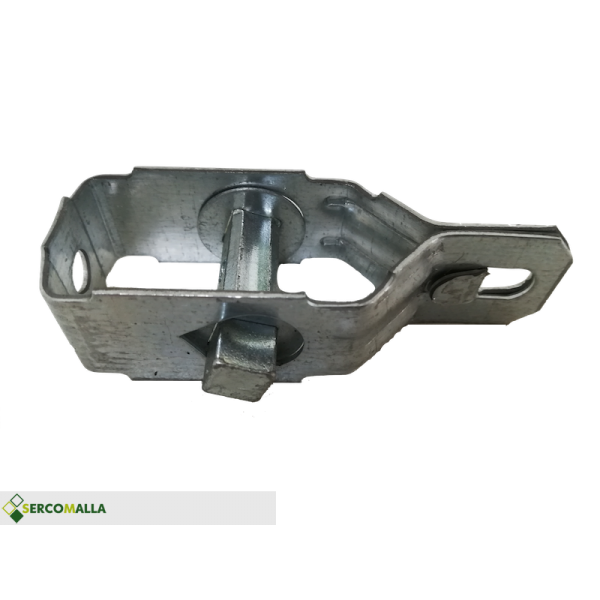

Amazon.com: US Cargo Control Tensor de mandíbula y mandíbula galvanizada de 1/2 x 12 pulgadas : Industrial y Científico

Manutención Tensor de Alambre de Acero Galvanizado Tensores para Malla de Alambre Pack 50 Alambre galvanizado emparrados Cable Tensor Jardin Entre Otros usos Vallas WooDlan Industrial Tela Metalica bendfoodproject.com